Wire Rope Sheaves Uk

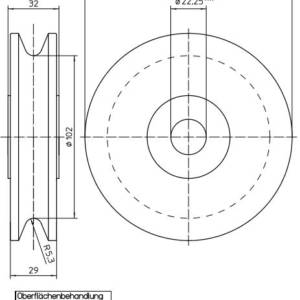

The concept is simple a circular steel or nylon plate grooved to accept a wire rope and bored to suit a bearing or bush.

Wire rope sheaves uk. Whilst this is the case there are many factors and standards to consider when designing and manufacturing sheaves and pulleys and the in depth knowledge and experience that sheaves uk offer is unrivaled. Contact now high quality hot rolled wire rope sheaves. We also offer a special bespoke design service where crosby will manufacture a pulley sheave to your specification. Pulleys with two grooves are for use where multiple pulleys move a single load such as block and tackle systems.

3 one side of the pulley blocks is hinged and can be opened for easy and quick positioning of the rope on the sheave. Contact now best sheave block pulley. For over fifteen years now sheaves inc. Contact now 5t snatch block specifications 1 use to change rope direction 2 used to change the direction of a rope with a cast steel sheave.

Has been the number one source for the wire rope industry designing and providing custom engineered wire rope sheaves that meet your specific needs and rigors of your application we also supply a large inventory of stock sheaves from the best known brands in the industry. They have a bracket on the bottom for tying off one end of your wire rope. We now also stock gmi galvanised steel iron pulley blocks with hook heads and also swivel oval eyes in a single and double sheave pattern. The correct design of sheaves and pulleys is critical and deviations away from recognised design standards can cause damage and premature wear to the wire rope resulting in large bills for replacements and machine down time.

Hang these pulleys from hooks screws and bolts to assist with horizontal pulling or to guide a rope. The solid steel plate provides the ideal surface for flame hardening an a closer tolerance fit to the wire rope fatigue and wear. 4 swinging the hook in the direction of pull. The mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140 contact area with the wire rope.

They require about half the force of a single groove pulley to move the same load. Crosby mckissick wire rope sheaves are available at many capacities diameters wire line sizes and bearing types.